Have you ever stopped to think about what makes large industrial facilities, like power plants or water treatment centers, run so smoothly? It's a bit like a hidden orchestra, with countless components working together, and at the heart of many of these operations are specialized devices that control the flow of liquids and gases. These devices, often called actuators, are incredibly important for keeping things moving just right, and when it comes to valve automation, Auma actuators are, well, pretty much everywhere you look, you know?

For anyone involved in keeping big systems operating, whether it's managing water supplies or generating electricity, the reliability of every single part truly matters. A small hiccup in one area can, in fact, cause a lot of trouble down the line, affecting everything from production schedules to safety. This is where the choice of equipment, particularly for valve control, becomes a very big deal, and Auma has, for a long time, been a name that many people trust in this space.

This article will take a closer look at what makes Auma actuators stand out, exploring their wide range of uses, the benefits they bring to various industries, and why they are often the preferred choice for automating valves in some of the most demanding environments. We will, you know, cover quite a bit of ground, so stick around to see how these devices help make the world run a little more efficiently.

Table of Contents

- What Are Auma Actuators?

- Why Auma Stands Out in Valve Automation

- Auma's Versatility: Handling All Valve Types

- Where Auma Actuators Make a Difference

- The Real Benefits of Auma Valve Automation

- Choosing the Right Auma Solution

- Frequently Asked Questions

What Are Auma Actuators?

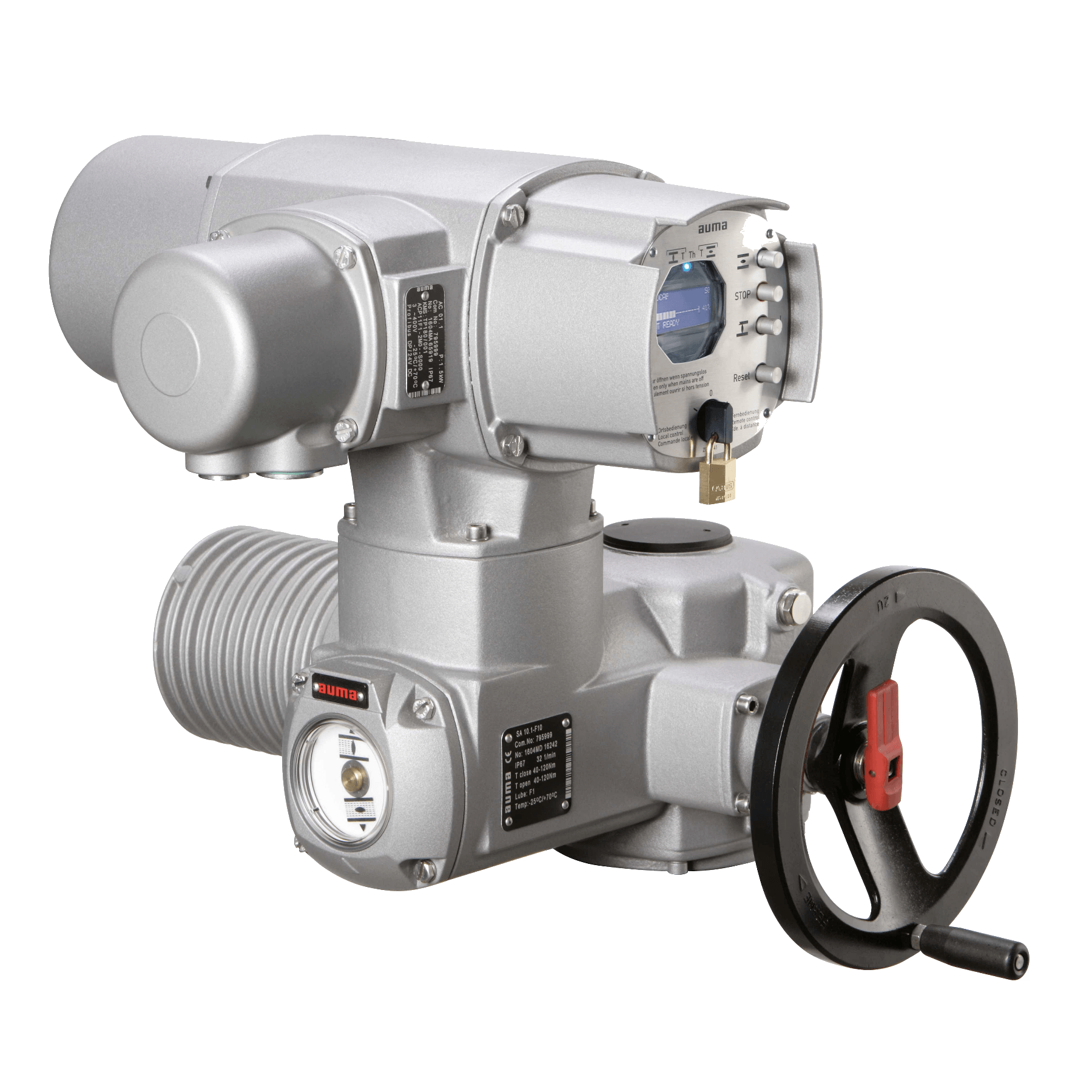

Think of an actuator as a kind of mechanical helper that takes a signal, say from a control room, and then turns it into physical movement. In the case of Auma, these are mostly electric actuators, which means they use electricity to open, close, or position valves. These valves, in turn, control the flow of things like water, oil, or gas through pipes.

Auma, you see, is a well-known maker of these electric actuators and also the gearboxes that often go along with them. Their equipment is used for automating valves, which just means making valves operate on their own or with very little human help. This kind of automation is, quite frankly, a big step up from having someone manually turn a valve wheel all the time, which, you know, can be very time-consuming.

These devices are, in some respects, the muscles of an automated system, receiving instructions from the brain, which is the control system. They are designed to be very precise and dependable, which is, well, pretty important when you're dealing with critical infrastructure. So, when you hear about Auma, you are basically hearing about a company that helps make industrial processes run with much more precision and less effort.

Why Auma Stands Out in Valve Automation

One of the reasons Auma has earned its reputation is its long-standing presence as a world leader in making these sorts of valve control devices. They've been at it for a while, and that experience really shows in what they offer. It's not just about making a single type of product; they have, you know, a whole array of options for different needs.

Auma provides many different ways to control their motors, including what they call integral and remote motor control packages. The integral motor controls, often known as Auma Matic, are pretty neat because they are built right into the actuator itself. This means you get a modern and, you know, quite economical way to manage the actuator's movements directly where it is.

Having both integral and remote options gives users a lot of flexibility. Sometimes you want the controls right there on the unit, and other times, you might want to manage things from a distance, perhaps in a central control room. Auma, you see, seems to understand that different situations call for different setups, which is a big part of their appeal. They really do offer a very wide range of choices, which is helpful.

Auma's Versatility: Handling All Valve Types

One very impressive aspect of Auma electric actuators is their ability to work with just about any kind of valve you can think of. This is, you know, a pretty big deal because there are many different valve designs out there, each with its own way of operating. Auma actuators are capable of operating all types of quarter-turn valves.

What are quarter-turn valves, you might ask? Well, these are valves that open or close with a 90-degree turn, a bit like turning a faucet handle. Common examples include butterfly valves, which look like a disc that rotates inside the pipe, and ball valves, which use a spherical ball with a hole through it to control flow. Plug valves are also in this group, so, you know, they handle a lot of common ones.

But it doesn't stop there. Auma actuators are also very good at managing multi-turn valves. These valves, as the name suggests, require several turns to go from fully open to fully closed, or vice versa. This group includes gate valves, which use a flat gate to block flow, globe valves, which regulate flow with a movable disc, and sluice gate valves, often found in water systems. Pinch valves, which squeeze a flexible tube to control flow, are also operated by these devices, so, you know, they really cover the whole spectrum.

Where Auma Actuators Make a Difference

Auma actuators find their way into a surprising number of places where precise flow control is needed. They are, in fact, widely used across many different industries, from the largest power stations to facilities that manage our drinking water. Their adaptability means they can be found in some very demanding settings, which is, you know, pretty cool.

Auma in Power Generation

When it comes to power plants, Auma actuators are a very common sight. They are, you know, specifically designed to work seamlessly with the sophisticated control systems found in these facilities. This means they can receive commands directly from the plant's central brain, ensuring that valves open and close at just the right moment, which is, you know, absolutely essential for generating electricity safely and efficiently.

In power plants, Auma actuators are characterized by their superior performance and ability to handle tough conditions. The environment in a power plant can be quite harsh, with high temperatures, vibrations, and constant operation. These actuators are built to withstand such conditions, ensuring they keep working day in and day out, which is, you know, a very important consideration for plant operators.

Auma for Water and Wastewater Management

Another area where Auma actuators are truly vital is in the management of water. This includes everything from treating drinking water to processing wastewater and even moving water through large pipelines. A complete range of actuators for use in water treatment plants, wastewater treatment plants, pumping stations, pipelines, and related facilities is available, so, you know, they've got it all covered.

In these settings, dependable valve actuation is absolutely key to ensuring public health and environmental protection. Whether it's controlling the flow of raw water into a treatment facility or managing the discharge of treated water, these actuators help maintain the delicate balance required for safe and effective operations. It's, you know, a critical role they play.

Auma in HVAC Systems

While often associated with heavy industry, Auma's influence also extends to areas like HVAC, which stands for heating, ventilation, and air conditioning. Companies like Ningbo Hoocon Automation Control Equipment Co., Ltd., which specializes in central air conditioning automatic control systems, do, you know, design, manufacture, and sell actuators for these applications. This shows how widely applicable the principles of valve automation are, even in buildings.

So, it's not just about big pipes and massive plants; Auma's technology, or the principles it represents, helps keep our indoor environments comfortable and efficient too. This is, you know, a very broad reach for a single type of product, which is pretty impressive. It really does show how versatile these kinds of devices can be, doesn't it?

The Real Benefits of Auma Valve Automation

Automating valves with Auma actuators brings several very clear advantages to any industrial operation. One of the biggest benefits is the proven increase in plant uptime. When valves can be operated remotely and reliably, there's less need for manual intervention, and problems can be addressed much faster, which, you know, keeps everything running smoothly.

Another significant advantage is the reduction in maintenance costs. Manual valve operation can lead to wear and tear on equipment, and it also requires more human labor. With automated systems, the actuators are designed for long-term, consistent operation, often needing less frequent checks and repairs. This can, you know, save a lot of money over time.

Perhaps most importantly, valve actuation is proven to increase plant safety. In many industrial environments, manually operating valves can expose workers to dangerous conditions, like extreme temperatures, hazardous materials, or moving machinery. By automating these tasks, personnel can stay out of harm's way, which is, you know, a truly invaluable benefit. It just makes things safer for everyone involved, which is, like, a top priority.

Choosing the Right Auma Solution

With such a wide array of applications and valve types, selecting the correct Auma actuator for a specific job is, you know, pretty important. Auma offers different series of actuators, such as the SA.2 and SQ.2, which are often combined with their specialized actuator controls. These combinations are designed to work together to provide optimal performance for various tasks.

For instance, the SA.2 actuators are generally used for multi-turn applications, while the SQ.2 actuators are typically for quarter-turn valves. Knowing which type of valve you have is the first step in picking the right Auma solution. It's, you know, a bit like choosing the right tool for a specific job, where having the exact fit makes all the difference.

Companies like Adqvalve Flow Control (Shandong) Automatic Control Technology Co., Ltd., are, you know, examples of businesses that work with these flow control technologies. They often help clients figure out the best Auma products for their unique needs, ensuring that the chosen actuator and its controls will perform exactly as expected in the given environment. It's all about making sure the parts fit the purpose, so, you know, it's pretty crucial to get it right.

Frequently Asked Questions

Here are some common questions people often ask about Auma actuators:

What types of valves can Auma actuators operate?

Auma electric actuators are capable of operating a very wide range of valves. This includes all types of quarter-turn valves, such as butterfly, ball, and plug valves, which only need a 90-degree turn to operate. They also work with multi-turn valves, like gate, globe, sluice gate, and pinch valves, which require several rotations to open or close fully. So, you know, they're pretty versatile.

What are the main benefits of using Auma actuators for valve automation?

Using Auma actuators for valve automation brings several key advantages. It's proven to increase plant uptime, meaning facilities can operate more consistently without unexpected stops. It also helps reduce maintenance costs because automated systems often require less frequent attention and are built to last. Perhaps most importantly, it increases plant safety by removing the need for human workers to manually operate valves in potentially dangerous areas, which is, you know, a very big deal.

Are Auma actuators suitable for use in power plants?

Absolutely, Auma actuators are, in fact, widely used and very well-suited for power plants. They are designed to offer an interface for all automated valves that can adapt to the complex power plant control systems. When used in power plants, Auma actuators are characterized by their superior performance and ability to withstand the demanding conditions often found in these environments. They are, you know, a very reliable choice for such critical applications.

To learn more about industrial automation solutions, you could, you know, check out resources like the International Society of Automation (ISA) at ISA.org. It's a great place to find information about standards and practices in the field.

You can learn more about valve control systems on our site, and to find out more about specific industrial applications for actuators, you can visit this page. We, you know, have quite a bit of information available for you.

Detail Author:

- Name : Dr. Maxwell Gerlach

- Username : trantow.stanley

- Email : rau.sandy@hotmail.com

- Birthdate : 2001-11-14

- Address : 672 Bryon Plains Apt. 170 Port Darienbury, ID 17423

- Phone : 934-375-4696

- Company : Hudson Inc

- Job : Animal Trainer

- Bio : Cum natus explicabo qui aut voluptatibus eos eos. Consequatur repellat quis autem nisi.

Socials

linkedin:

- url : https://linkedin.com/in/keonkutch

- username : keonkutch

- bio : Voluptatibus ratione praesentium non minima.

- followers : 413

- following : 1057

facebook:

- url : https://facebook.com/keonkutch

- username : keonkutch

- bio : Voluptatem ratione amet qui enim beatae molestiae doloremque nobis.

- followers : 901

- following : 576

twitter:

- url : https://twitter.com/keonkutch

- username : keonkutch

- bio : Non et et omnis. Repellat amet quo consequatur in. Et culpa rerum in omnis dolorem officia. Facilis ipsum vel dolor aut fugit et dolor.

- followers : 3610

- following : 1864